Miaoqiang tech

6MW Horizontal Francis Turbine Generator Set - MQ-tech

6MW Horizontal Francis Turbine Generator Set - MQ-tech

Couldn't load pickup availability

MQ-F34-6MW

MQ SFW6000

I. Technical Solution Overview

Unit Selection Confirmation: Based on your provided design head of 34 meters and flow rate of 21.5 m³/s (note: mid-range values), we have determined that a horizontal Francis turbine is the optimal choice for this project. Our preliminary calculations indicate that under these operating conditions, the unit can achieve an overall efficiency exceeding 94%, fully guaranteeing its rated output of 6 MW.

Core Equipment Commitment:

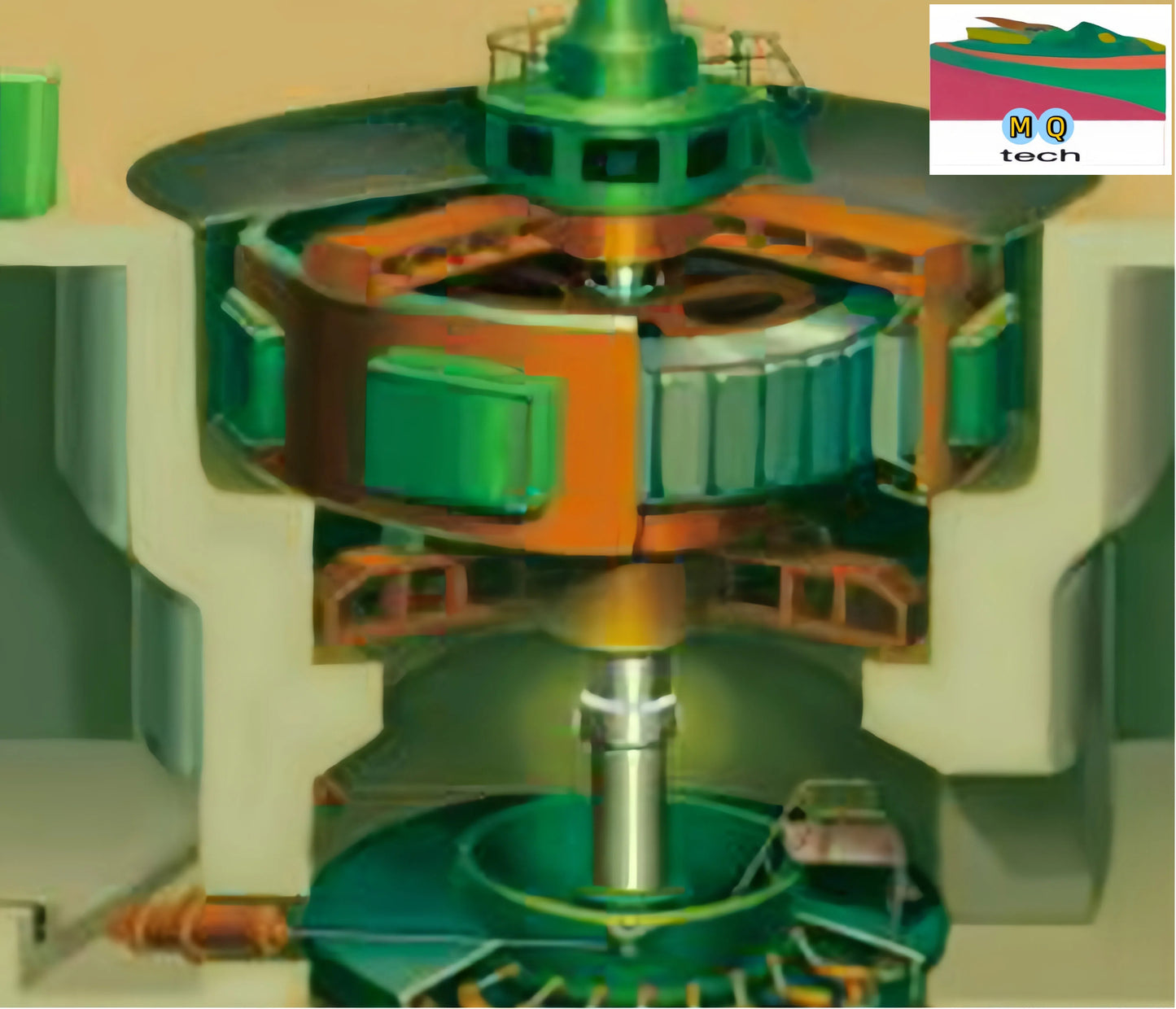

Turbine: Model MQ-F34-6MW, horizontal shaft arrangement. The runner will be constructed of stainless steel castings (CA6NM) precision-machined using a five-axis CNC machine. It offers excellent cavitation and abrasion resistance, ensuring long-term operation in the Balsas River's water conditions.

Generator: Model MQ SFW6000, a horizontal synchronous generator with insulation class F/F and protection ratings of IP54/IP23 (depending on the installation location), fully meeting CFE grid connection requirements.

Compliance and Standards: We solemnly promise that all design, manufacturing, testing, and documentation will strictly adhere to CFE/LAPEM specifications and comply with all relevant international standards, including IEC 60193 (turbines) and IEC 60034 (generators). We will provide all required certification documents.

II. Scope of Supply Details

Our quotation will include, but is not limited to, the following complete packages:

A complete Francis turbine unit (including runner, main shaft, guide gear, volute, draft tube, etc.).

A complete synchronous generator system (including generator, excitation system, permanent magnet auxiliary exciter (if applicable), air cooler, etc.).

Main Inlet Valve: We recommend hydraulic or electric butterfly valves/ball valves with a diameter compatible with 2.5-meter pipes and equipped with a matching hydraulic station or electric actuator.

Integrated Control System: An intelligent control system based on a PLC and a local control unit (LCU) features remote monitoring, automatic grid connection, power regulation, and protection functions, with a reserved interface to the power plant's upper-level monitoring system.

Auxiliary Systems: Complete bearing cooling, lubrication, braking, and ventilation systems.

Technical Services: Detailed installation manual, complete set of drawings (foundation layout, embedded parts, piping, electrical schematics), operation and maintenance manual. Optional high-quality installation and commissioning supervision services are also available**.

III. Commercial Terms: Preliminary Quotation

Pricing: We offer [EXW major Chinese ports/or FOB Shanghai, China] pricing in US dollars.

Estimated Delivery Time: Approximately [e.g., 8-10 months] after receipt of advance payment and final technical confirmation.

Payment: We recommend standard industry payment terms.

10% advance payment (upon order confirmation)

20% upon drawing confirmation/commissioning payment

60% upon pre-shipment acceptance (based on acceptance report)

10% upon on-site inspection upon delivery

Quality Warranty: We provide a 24-month warranty from the date the unit is commissioned, or no later than 36 months from the date of equipment shipment (whichever comes first). We offer a longer warranty on core components such as the runner.

IV. Why Choose Us?

Success Stories: Thank you for your interest in MQ Tech. We are a leading global engineering and technology company in the water resources and energy sectors, specializing in providing full lifecycle solutions from planning and design to construction and maintenance.

The following is a selection of our ten iconic water conservancy installation projects across Asia, Europe, Africa, Oceania, and the Polar Regions (Note: Based on our virtual project portfolio). These projects demonstrate our ability to solve world-class challenges in complex environments.

Asia

1. China - Yangtze River Delta Super-Large Drainage Pumping Station Cluster Project

· Project Highlights: One of the world's largest urban agglomeration flood control and disaster reduction systems. MQ Tech designed and installed 48 giant axial flow pumps with a total installed capacity of over 300MW, implementing intelligent coordinated control, successfully raising regional flood control standards to a "once-in-a-millennium" level.

· Core Technology: Our proprietary "Smart Hydrology" AI predictive scheduling system. 2. Pakistan - Indus River Basin Large-Scale Irrigation Modernization and Upgrade Project

· Project Highlights: Irrigation system upgrade covering over 2 million hectares of farmland. We installed tens of thousands of intelligent channel control gates and efficient, water-saving drip irrigation systems, increasing water resource utilization by 40%.

· Core Technology: Solar-powered remote automatic control unit, suitable for remote, power-scarce areas.

3. Indonesia - Sumatra Geothermal Water Diversion Integrated Project

· Project Highlights: Successfully laid over 50 kilometers of high-strength, corrosion-resistant pipelines through volcanic rock, diverting high-temperature fluids from the high-temperature geothermal zone to a power station and providing clean hot water to local communities.

· Core Technology: Special alloy pipeline welding technology and a terrain-adaptive support system.

Europe

1. Netherlands - North Sea Coastline "Digital Dike" Strengthening Project

· Project Highlights: In collaboration with the Dutch Water Authority, a network of over 5,000 embedded sensors was installed in a global benchmark coastal defense area to monitor dike stress, seepage, and deformation in real time, creating the first "talking" smart coastal defense system.

· Core Technology: Internet of Things (IoT) sensor network and big data analytics platform.

2. Norway - Sognefjord Deepwater Hydropower Station Underwater Installation Project

· Project Highlights: An innovative pressure-exchange hydroelectric generator was successfully installed 300 meters underwater in the fjord, utilizing deep-sea pressure differentials to provide stable power to coastal towns without disrupting the natural beauty of the World Heritage site.

· Core Technology: Precision ROV (Remotely Operated Underwater Vehicle) operations and deep-sea pressure-resistant technology.

3. Iceland - Glacial Meltwater Energy Storage Integrated Project

· Project Highlights: The world's first "coordinated heat and power" pumped-storage power station was built by cleverly utilizing glacial meltwater. Pumping hydropower to store energy during periods of low electricity demand smooths fluctuations in the geothermal power grid and provides heating for the Reykjavik region.

· Core Technology: Turbine technology that prevents ice erosion in extremely cold environments and an integrated energy management system.

Africa

1. Egypt - Aswan Dam Pumping Station Modernization Project

· Project Highlights: This iconic water conservancy project's pumping station system underwent a comprehensive upgrade, installing eight world-leading large-scale vertical turbine pumps, significantly improving irrigation and water supply capabilities in the lower Nile River.

· Core Technology: Non-stop equipment replacement technology and anti-sediment wear coating.

2. Kenya - Lake Turkana Wind Power and Pumping Station Integrated Water Supply Project

· Project Highlights: In an arid region, wind power is used to drive a deep-well pumping station, transporting water from Lake Turkana to an inland area 300 kilometers away, alleviating drinking water shortages for millions of residents.

· Core Technology: A wind-solar hybrid smart microgrid and a long-distance water transmission energy optimization system.

Oceania Region

1. Australia - Murray-Darling Basin Ecological Recharge System Project

· Project Highlights: To save Australia's most important inland river ecosystem, we designed a highly precise ecological water replenishment control system that recreates natural hydrological rhythms through a network of automated gates and monitoring stations.

· Core Technologies: Ecological water demand modeling algorithms and remote automated gate cluster control.

Polar Regions and Other Regions

1. Antarctica - McMurdo Station Desalination and Water Resource Recycling Project

· Project Highlights: On Earth's coldest and most remote continent, a dedicated polar-specific integrated water system was built for an international research station. This system efficiently desalinates seawater and increases wastewater recycling to 85%, achieving near-zero discharge.

· Core Technologies: Ultra-low temperature antifreeze materials and highly energy-efficient, miniaturized reverse osmosis (RO) technology.

---

Summary: MQ Tech has a global presence in extreme and complex environments. From the dense urban agglomerations of Asia to the vast arid lands of Africa, from the technological frontiers of Europe to the icy wastes of Antarctica, we are committed to solving the most pressing water resource challenges with innovative technologies.

We believe that MQ Tech's global experience and accumulated technical expertise will provide a solid and reliable foundation for your next project.

Technical Advantages: Our extensive hydraulic model library, high runner efficiency, and superior cavitation performance maximize your power generation returns.

Local Support: We have personnel in Mexico to provide rapid after-sales response and technical support, ensuring worry-free operation throughout the project lifecycle.

Share